I’m so excited to level out you the office towers that are part of my massive DIY Office Desk System! Our office was the ultimate room, in our new house, that I hadn’t touched and it was prolonged overdue. I needed to create an space that my hubs may go comfortably, a spot that my kids may go in and a spot that I didn’t actually really feel I needed to shut the doorways when agency was over anymore 😉 That required, open shelving (sensible nonetheless participating) and hidden storage (to cowl the complete office junk).

With that in ideas, I acquired to designing and created this! I designed two towers with hidden storage for our printer, info and gives and open storage for the attractive points. I moreover wished the desk to look like it was part of cupboards, like one prolonged shelf. You’ll uncover the plans for the desk HERE!

This tutorial is for the towers. It does have pretty a few steps nonetheless as always, I’m sharing the free printable plans and the step-by-step tutorial to interrupt all of it down for you. You presumably can click on on HERE or the image beneath to print your free plans!

There are angle cuts nonetheless don’t let that scare you away, I am exhibiting you the way one can merely make them AND, they don’t must be good 🙂 So, let’s get started!

I started by decreasing all of my shelf objects.

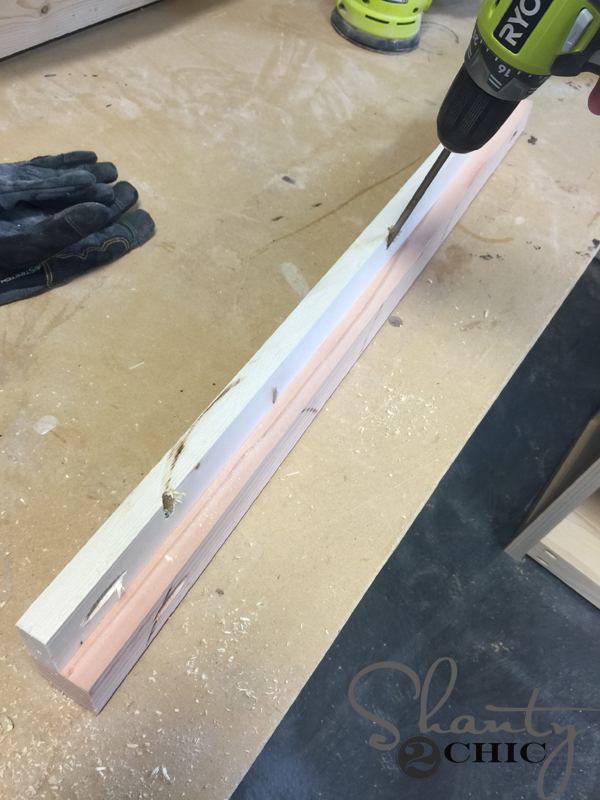

Then, I used my Kreg K5 to drill 3/4 pocket holes throughout the shelf objects (search recommendation from the plans for pocket hole placement). You presumably can click on on HERE for our Tips about easy methods to Use a Kreg Jig Video and click on on HERE to purchase a Kreg Jig K5 on Amazon.

Subsequent, I related the shelf objects together with 1 1/4″ pocket hole screws.

Proper right here is one shelf piece, assembled.

I had my massive sheets of Purebond Plywood ripped at Home Depot, so that I could get them in my automotive. Then, I used my miter observed to cross-cut the plywood objects to dimension.

I related the shelf objects to the plywood side objects with 1 1/4″ pocket hole screws (search recommendation from the plans for the shelf placement).

That’s what your cabinet base should look like now. Two plywood sides and one shelf.

Now, join the best and bottom objects with wood glue and 1 1/4″ brad nails. I make the most of my 18 gauge Ryobi Airstirke Nailer.

Proper right here is the cabinet base with the underside related.

And proper right here is the cabinet base with the best related.

Now it’s time to assemble the “ladders” (the side objects of the towers).

To keep away from losing on lumber worth, I used my desk observed to tear 2×4 boards to create 2×2’s. The select pine 2×2’s are about $8 each at my ironmongery store and the 2×4’s are solely $3 AND I can get two 2×2’s per 2×4. I moreover did this for the 1×2 boards. I purchased 1×4 boards and made two 1×2’s out of each board. Full, this saved me about $150 in lumber, setting up two towers. You can purchase a main Ryobi desk observed for about $129, so this generally is a good choice to justify together with to your software program assortment 😉

Slicing the boards down does require a bit of additional work nonetheless on this case, it was properly well worth the monetary financial savings. I used my Ryobi 18-volt orbital sander to scrub the boards out.

And proper right here they’re, ready to utilize 🙂

Sooner than you start to assemble the “ladders” measure the width of the cabinets you constructed and decrease the horizontal rails to this dimension. It can make the “ladders” match the cabinet utterly.

Decrease the horizontal rails to that measurement and drill pocket holes in response to the plans.

To assemble the “ladders” I created spacers so that both facet of the towers had been exactly the an identical. It can make your cupboards good and diploma 🙂 I related the 2×2’s to the rails with 1 1/4″ pocket hole screws and wood glue.

Proper right here is one “ladder” achieved.

Now, flip the cabinet on its side

and clamp a “ladder” on excessive of it (search recommendation from the plans for the precise measurements for the inset on the underside.

Join the “ladder” with wood glue and 1 1/4″ brad nails.

As quickly because the “ladders” are every related, decrease the doorway, 2×3 trim objects to go well with and fasten them with wood glue and pocket hole screws.

Then, shoot a few 2″ brad nails into the 2×3’s from the floor 2×2 “ladder” frames, for added assist.

That’s what it will look like at this degree.

Then, join the once more trim objects with pocket hole screws and wood glue.

Now, assemble the brace for the once more of the hutch with 1×2 and a few×3. This offers you a spot to attach the once more plywood panel to.

Join the brace to the once more of the cabinet with wood glue and a few 1/2″ pocket hole screws.

Proper right here is is related to the once more of the cabinet. (At this degree, you presumably can join your once more panel with staples, must you select. I prefer to attend until the tip so that I can stain the panel after which join it. This makes it less complicated to stain the shelf objects).

Now, you’ll be able to start attaching the doorway horizontal objects. Use wood glue and a few 1/2″ pocket hole screws.

Proper right here is the tower with the doorway horizontal objects related. Now for the once more objects.

Everytime you start attaching the once more rails, make sure to concentrate to the inset for the 1×3 piece.

(Seek the advice of with the plans for the exact measurement on the inset).

Now for the cleats. Measure and decrease the 1×2 objects to dimension and drill 3/4″ pocket holes in response to the plans. Join them with 1 1/4″ pocket holes screws and wood glue. These cleats will preserve the cupboards that we constructed firstly!

Proper right here is one shelf with the cleats put in.

Upon getting the cleats put in, begin inserting the shelf objects inside. It could almost definitely be a comfortable match so that you presumably can each use a mallet to knock them in place or, it’s best to use a scrap piece of wood and a hammer. It can protect you from damaging the wood.

Protected the shelf to the cleats with 1 1/4″ brad nails and wood glue.

Transferring on to the “x” objects on the once more. Start with one the first 1×2 piece that will stretch nook to nook. Mark a line the place the 1×2 meets the 2×2 “ladder” physique.

Now, merely switch the miter (bottom) part of your observed until it traces up with the angle you’ll have made. This takes the complete guess work out and gives you a really perfect match 🙂

Then, lay the board down in place and mark for the best nook angle.

Do the an identical for the next to objects.

In the event you want to paint the “x” piece black, like I did, then do not join these however. Mark them with labels that you’re going to keep in mind the place each bit goes and put them off to the side.

Now for the trim on the underside! Measure and decrease to go well with the 1×3 trim objects for each side of the cabinet. Join them with wood glue and brad nails.

As quickly as every trim objects are related, measure and decrease to go well with the doorway piece of trim.

Apply wood glue to the piece

and nail it in place 🙂

Door time!!

Measure and decrease the objects to assemble the door physique. Drill 3/4″ pocket holes, in response to the plans, and be a part of the objects with 1 1/4″ pocket hole screws and wood glue. **Make it attainable for must you plan to stain the piece, that you just use the wood glue sparingly. Picket glue is simply not stainable and it is arduous to remove it totally as quickly because it has leaked”.

One door physique achieved.

Listed beneath are the door frames for each door. Dry match them in place to confirm they match sooner than you join the 1/4″ plywood backs. It is so much less complicated to make modifications at this degree than it is as quickly because the backing is on – perception 😉

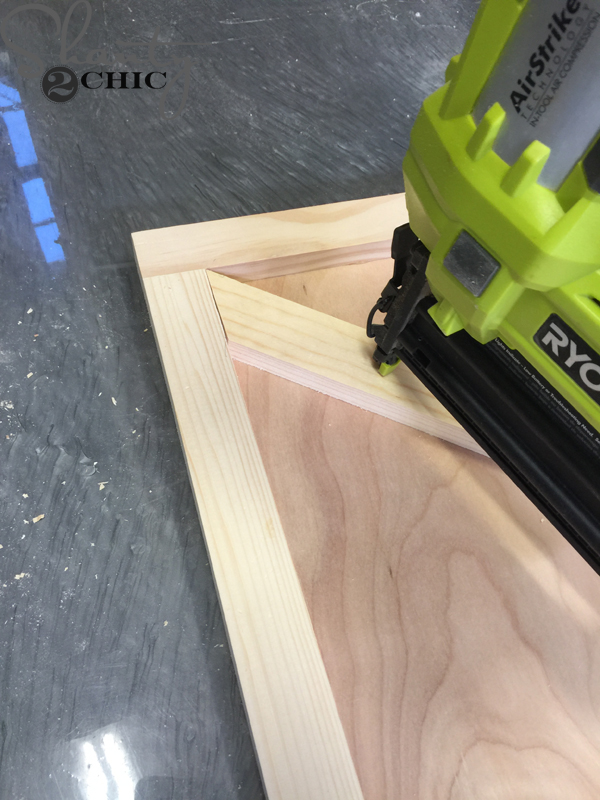

Decrease the 1/4″ plywood objects to go well with the door frames and fasten it to the frames with wood glue and three/4″ staples. I used my Airstrike Stapler nonetheless must you don’t have a stapler, it’s best to use brad nails nonetheless the staples are best for attaching 1/4″ supplies.

That’s what the door will look like with the backing.

To cut the “x”objects for the doorways, use the an identical strategy we used for the “x” objects on the once more. Start with the best nook and mark to your decrease.

Make your first decrease

then mark for the second decrease.

Join the objects to the door with wood glue and three/4″ staples.

Good job, now you are ready for stain 🙂

I chosen Early American stain by Varathane for these guys! We love using Varathane stain because of it goes on very rich and in just one coat AND it dries in a single hour!!!

I launched them inside to stain because of it was just too darn chilly in my retailer. I used a lambs wool applicator to make use of one coat of stain over your full piece. I actually prefer to make use of those applicators once I’m staining huge objects. It makes it so quick and easy!

As you apply the stain, let some dry for about 5 minutes after which return and blend the stain in with a transparent material. So, I will stain for about 5 minutes after which return and blend what I merely stained after which switch on to the next spot. You don’t must wipe the stain away, merely combine it so that it’s even.

Now, merely let the stain dry for about an hour then, I began the distressing!

I used my orbital sander to distress your full tower! I actually just like the worn look it provides this Early American Stain!

For the hard-to-reach areas, I used my nook cat!

Subsequent, I used Rust-Oleum Chalk Board spray paint to paint the “x” objects for the once more.

Then I related them with my brad nailer to the once more of the towers.

Remaining, I related the once more panel to the tower after which related the doorways with hinges!

Final step – the top! Get a moist clear material and wipe down the complete mud, from the distressing. Then, you are ready for the top! I LOVE using Varathane Triple Thick Polyurethane. One coat is identical as three coats and it dries fast! I apply a thick coat on (it should look like glue) with a bristle brush. When it dries, will in all probability be clear and clear! I went with Satin finish.

That’s it! Full for the two towers collectively was about $300 in lumber. If I had bought the 2×2’s and 1×2’s reasonably than ripping them from cheap boards, it is going to have have worth me about $450 in lumber.

I’ll be once more shortly to share the floating desk that’s in between the towers!

Fascinated with the place the entire fulfilling stuff is from?

Left tower:

Excessive shelf: Tall plant – HomeGoods, Succulent – Purpose, Collectible collectible figurines – Purpose

Second shelf: E-book Ends – Save On Crafts, Feather Paper Weight – Purpose, Physique – HomeGoods

Third Shelf: Frames – HomeGoods, Succulent – Purpose, Clip boards – Purpose

Bottom Shelf: Wire drawers – Purpose, Pencil and Pen tins – World Market, Glass Jars – Purpose

Correct Tower:

Excessive Shelf: Bins – Purpose,

Second Shelf: Vase – Purpose, Succulent – Purpose, Owl – Curiosity Lobby

Third Shelf: Physique – Curiosity Lobby, Printable in Physique – HERE, Gold Geometric Ball – Purpose

Bottom Shelf: Physique – HomeGoods, Magnetic Calendar – Curiosity Lobby, Metal Tray and Grey Buckets – Purpose

Cork Board Physique on Wall – Curiosity Lobby (bought cork board and an empty physique and stapled it collectively)

Chair – Pier 1

Pillow – Purpose

Thanks so much for stopping by!

Utterly completely happy Setting up!