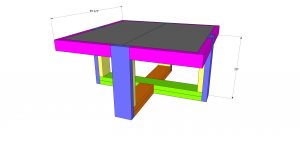

Uncover methods to assemble this DIY Sq. Espresso Desk with free plans and a step-by-step tutorial by Shanty2chic!

I am nonetheless on a mission to revamp rooms in my residence by setting up new furnishings! I’m engaged on the lounge and starting with a model new espresso desk. My earlier desk was chewed up pretty unhealthy by our pet so it’s an unbelievable one to start out out with!

Let’s get setting up! Merely click on on the sector beneath to have a look at the how-to video!

Click on on proper right here to leap to the free plans!

The precise option to assemble a DIY Sq. Espresso Desk

Devices:

Offers:

- 5 – 2x6x8 Pine or Framing Lumber

- 2 – 2x4x8 Pine or Framing Lumber

- 2 – 1×24″x48″ Problem Panel

- 1 1/4″ Pocket Hole Screws

- 2 1/2″ Pocket Hole Screws

- 1 1/4″ Brad Nails

- 2″ Brad Nails

- Wood Glue

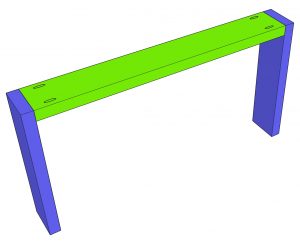

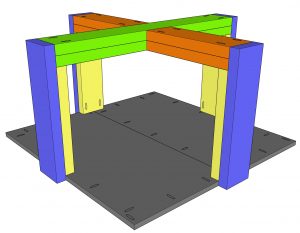

Setting up the Base

Step 1

Scale back the leg objects to measurement and drill 1 1/2″ pocket holes consistent with the scale back guidelines. I used my Kreg Foreman for this mission. It’s good in case you’re setting up alot of big objects on account of it makes the work sooner!

In case you might be setting up in your dwelling our favorite pocket hole software program is the Kreg Jig K5!

Join the underside runner to 2 legs with 2 1/2″ pocket hole screws and picket glue.

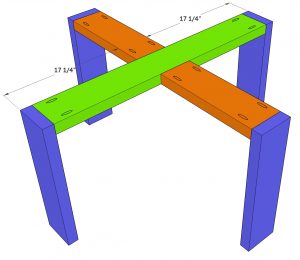

Step 2

Join the two bottom fast runners to a leg and fasten the fast runners to the center of the prolonged runner with 2 1/2″ pocket hole screws and picket glue.

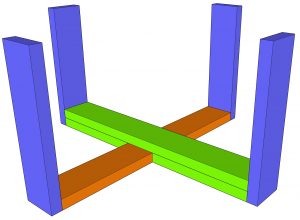

Step 3

Flip the desk base right-side-up and fasten the second prolonged runner to the best of the underside runner with 2″ brad nails and picket glue.

Step 4

Join the second fast runners to the best of th ebottom fast runners with 2″ brad nails and picket glue.

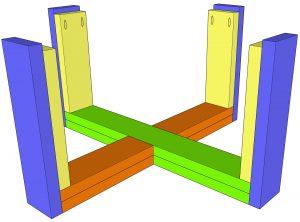

Step 5

Join the fast legs to the prolonged legs with 2″ brad nails and picket glue. The underside of the fast legs must be flush with the best of the prolonged runner.

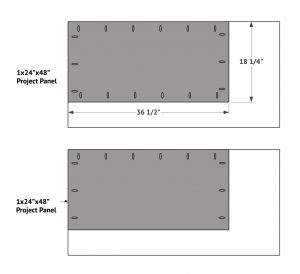

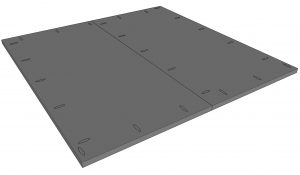

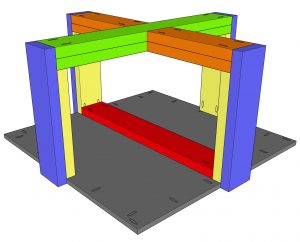

Setting up the DIY Sq. Espresso Desk Excessive

Step 1

Scale back the best mission panels to measurement and drill 3/4″ pocket holes spherical all edges of 1 and three edges of the other. Join them together with 1 1/4″ pocket hole screws and picket glue.

Step 2

With the tabe prime the opposite means up, flip th ebase the opposite means up on prime of it, so that the fast legs are resting on the best of the desk prime. Join the desk prime to the fast legs with 1 1/4″ pocket hole screws and picket glue.

Step 3

Scale back the assistance piece to measurement and drill 1 1/2″ pocket hole screws at every ends. Join it over the desk prime seam, to the legs with 2 1/2″ pocket hole screws and picket glue and fasten it to the desk prime with 2″ brad nails.

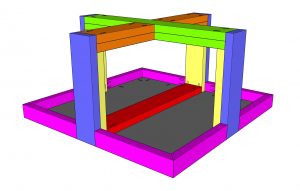

Desk Excessive Trim

Step 1

Measure and scale back the trim objects to measurement and drill 1 1/2″ pocket hole screws to each sq. end. Join them to the desk prime with 1 1/4″ pocket hole screws and fasten them to the desk legs with 2 1/2″ pocket hole screws and picket glue. Add a few 2″ brad nails and picket glue on the corners to affix the 45° angles collectively.

The Finish!

Step 1

As quickly because the desk is constructed, fill any uncovered pocket and nails holes with picket filler and sand it down with 80-grit sandpaper adopted by 120-grit after which 220-grit. As quickly because the sanding was executed I used a Minwax pre-stain picket conditioner.

Step 2

For the tip, I blended 2 parts Minwax picket finish in Golden Oak with 1 half Fundamental Gray.

Their new Wood Finish line is very easy to utilize! Merely wipe the stain with a rag. It solely requires one coat and dries in a few hours!

Step 3

To protect the tip I tried a model new product! Minwax Comfy Contact Ending Wax. These things is superior and very easy to utilize!

Merely open the lid and stir the wax.

Then, wipe the wax over the picket in a spherical pattern.

Let the wax sit for 5-Quarter-hour and buff it with a transparent materials.

That’s it! I just like the matte finish and it was truly no mess! It actually works on stained, painted and raw picket!

Thanks so much for stopping by!

Joyful Setting up!

Further Espresso Desk Builds

Chunky Espresso Desk

Industrial Espresso Desk

Spherical Espresso Desk

DIY Sq. Espresso Desk

Devices

-

Desk Observed (elective)

-

Miter Observed

-

Drill

-

Kreg Jig

-

Brad Nailer

-

Sander

Instructions

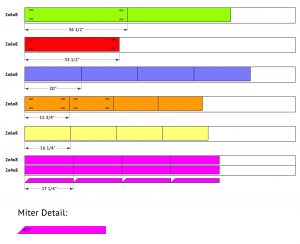

Scale back File

-

Scale back File 1

-

Scale back File 2

Setting up the Base

-

Scale back the leg objects to measurement and drill 1 1/2″ pocket holes consistent with the scale back guidelines. Join the underside runner to 2 legs with 2 1/2″ pocket hole screws and picket glue.

-

Join the two bottom fast runners to a leg and fasten the fast runners to the center of the prolonged runner with 2 1/2″ pocket hole screws and picket glue.

-

Flip the desk base right-side-up and fasten the second prolonged runner to the best of the underside runner with 2″ brad nails and picket glue.

-

Join the second fast runners to the best of th ebottom fast runners with 2″ brad nails and picket glue.

-

Join the fast legs to the prolonged legs with 2″ brad nails and picket glue. The underside of the fast legs must be flush with the best of the prolonged runner.

Setting up the Desk Excessive

-

Scale back the best mission panels to measurement and drill 3/4″ pocket holes spherical all edges of 1 and three edges of the other. Join them together with 1 1/4″ pocket hole screws and picket glue.

-

With the tabe prime the opposite means up, flip th ebase the opposite means up on prime of it, so that the fast legs are resting on the best of the desk prime. Join the desk prime to the fast legs with 1 1/4″ pocket hole screws and picket glue.

-

Scale back the assistance piece to measurement and drill 1 1/2″ pocket hole screws at every ends. Join it over the desk prime seam, to the legs with 2 1/2″ pocket hole screws and picket glue and fasten it to the desk prime with 2″ brad nails.

Desk Excessive Trim

-

Measure and scale back the trim objects to measurement and drill 1 1/2″ pocket hole screws to each sq. end. Join them to the desk prime with 1 1/4″ pocket hole screws and fasten them to the desk legs with 2 1/2″ pocket hole screws and picket glue. Add a few 2″ brad nails and picket glue on the corners to affix the 45° angles collectively.

The Finish

-

Now merely fill your pocket holes and nails holes with picket filler, sand it down and add a finish! Ensure that to share your builds with us on social media and use #shanty2chic so we’re capable of share them too! Joyful Setting up!